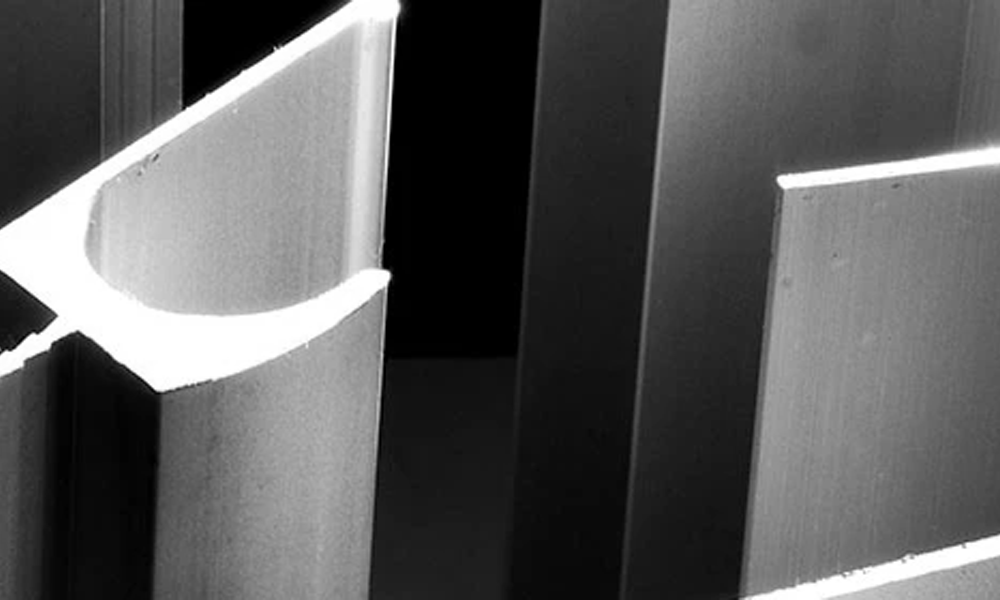

The extrusions manufactured by Profall are made with so-called soft alloys: these are essentially the alloys that belong to the 1000, 3000 and 6000 series.

Get your free PDF catalog containing the physical and mechanical properties of all aluminum alloys we use.

In terms of aluminum content, alloys of the 1000 series have a minimum purity rating of 99.5%. This gives them a high capacity in terms of electrical and thermal conductivity. Furthermore, they are also extremely resistant to corrosion. They are typically utilized in the electrical and electromechanical industries.

| Property | Value (indicative) |

|---|---|

| Purity | ≥ 99.5% |

| Density | 2.70 g/cm³ |

| Conductivity | 60–65% IACS |

| Corrosion resistance | ★★★★★ |

| Workability | ★★★★★ |

Alloys of the 3000 series, which are mainly composed of manganese, offer even greater resistance to corrosion, and are generally utilized for braze welding purposes. Products made using alloys of the 3000 series are typically utilized for heat exchangers and automotive applications.

| Property | Value (indicative) |

|---|---|

| Major alloying element | Manganese |

| Density | ~2.73 g/cm³ |

| Corrosion resistance | ★★★★★ |

| Workability | ★★★★☆ |

Alloys of the 6000 series, on the other hand, contain Silicium and Magnesium. This family of soft alloys is characterized by its ease of processing and welding. In fact, these alloys are commonly used to manufacture welded structures and machined components. They are used to manufacture the majority of all specially-designed extrusions for industrial uses. This family includes one of the most used alloys in the extrusion industry: 6063 aluminum, widely employed to manufacture aluminum bars and tubing.

| Property | Value (indicative) |

|---|---|

| Major alloying elements | Silicon, Magnesium |

| Density | ~2.70 g/cm³ |

| Workability | ★★★★☆ |

| Weldability | ★★★★★ |

| Corrosion resistance | ★★★★☆ |

Profall utilizes a wide range of aluminum alloys: 1050 – 1070 – 3003 – 3103 – 3004 – 6060 – 6063 – 6005.

Thanks to the versatility of our aluminum alloy extrusion profiles, Profall serves a wide range of industries. Each alloy series is selected to meet the specific requirements of different sectors, ensuring the perfect balance of strength, corrosion resistance, conductivity, and workability. Below are the main fields where our alloys are most commonly applied.

3000 and 6000 series alloys are widely used in the automotive industry for heat exchangers, structural parts, and lightweight components thanks to their excellent corrosion resistance and formability.

1000 series alloys are ideal for conductive components used in electrical and electromechanical systems, due to their high purity and superior conductivity.

6000 series alloys are perfect for welded structures, frames, and custom aluminum alloy extrusion profiles designed for industrial machinery, building systems, and architectural elements.

6000 series alloys, in particular 6061 and 6063, are well-suited for marine aluminum alloy applications due to their excellent corrosion resistance in marine environments, including exposure to saltwater and high humidity.

These alloys combine lightweight properties with good mechanical strength, making them ideal for a variety of marine structures.

Their high weldability ensures reliable assembly of complex structures without compromising integrity, while their good anodizing response allows for additional surface protection and aesthetic finishes where required.

Common applications include:

Choosing marine aluminum alloy extrusion profiles made from 6000 series alloys ensures durability, low maintenance, and long-lasting performance even in the harshest conditions at sea.

At Profall, we are specialists in the design and production of custom aluminum alloy extrusion profiles tailored to meet the most demanding requirements of industries such as automotive, electrical, architectural, and marine.

Our expertise covers the full spectrum of alloys aluminum processing, from the selection of the most suitable alloy to the development of precision profiles that meet stringent technical and aesthetic standards.

Our technical team works closely with clients to:

Contact us for customized solutions, technical advice, or sample requests. Together, we will bring your projects to life with the highest precision and reliability.

Aluminum profiles for every need, including those with hard-to-achieve technical characteristics.

With Profall, you have access to a world of unique possibilities, where every challenge finds its tailored solution.

Discover all the insights into our service for supplying standard profiles or custom extrusions based on customer designs and specifications.

Create without limits: get a quote for your custom aluminum profile.