In this article, we will delve into:

- L-shaped aluminum profiles

- Aluminium alloys

- Customized L-shaped aluminum profiles

- The versatility of these products

- The service Profall guarantees

L-shaped aluminum profiles: what are they?

L-shaped aluminum profiles are extrusions with sides forming a 90° angle. Their sides can have the same length or a different one. Profall is able to manufacture the L-shaped profile that most suits your needs, even with a special design and small or very small dimensions.

Let’s see together the products in our catalog.

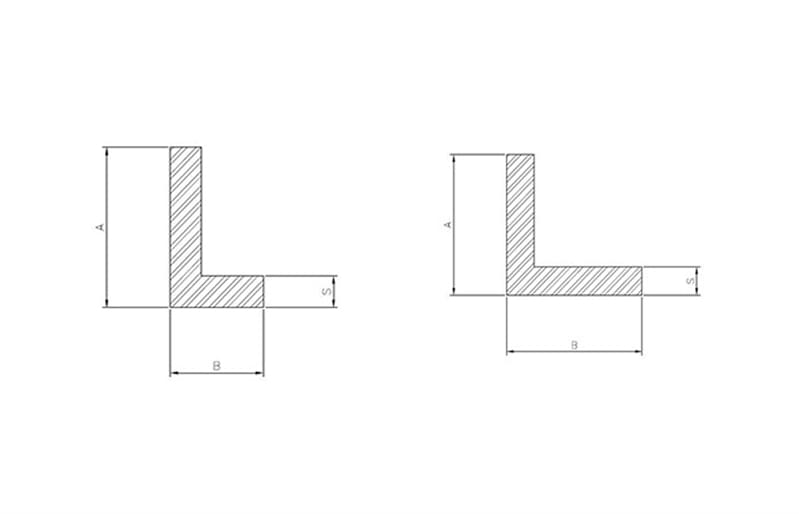

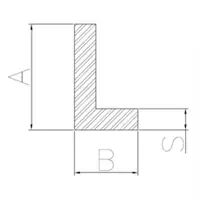

L-shaped aluminum corner extrusions with even sides

Aluminum corner extrusions with even sides are L-shaped standard profiles whose sides have the same length. They are made by resorting to the qualities offered by the following aluminum alloys: 1050, 1070, 3103, and 6060.

Thanks to their versatility, they find widespread use in the following commercial and industrial sectors:

- electronics and robotics

- furnishing – even technical

- constructions

These profiles are supplied in the bar format, with a minimum order quantity of 300 kg.

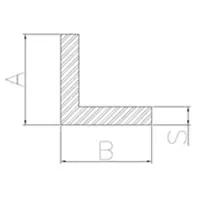

L-shaped aluminum corner extrusions with uneven sides

As opposed to these last ones, aluminum corner extrusions with uneven sides are L-shaped standard profiles whose sides differ in length. They are still made resorting to the qualities offered by the following aluminum alloys: 1050, 1070, 3103, and 6060.

Thanks to their resistance to shock, corrosion, and environmental agents, they find widespread use in the following commercial and industrial sectors:

- mechanics and electromechanics

- domestic

- constructions

These profiles are supplied in the bar format, with a minimum order quantity of 300 kg.

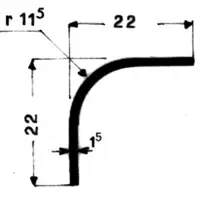

L-shaped aluminum corner extrusions with special cross section

Finally, our catalog also includes a third type of L-shaped aluminum profile – corner extrusions with special cross section. These are made resorting to the qualities offered by the 6060 aluminum alloy.

They often present a knurled surface and are mainly used as finishing elements for:

- panels

- edge elements of steps

- industrial vehicles

These L-shaped aluminum profiles are supplied in the bar format, with a minimum order quantity of 300 kg.

Which L-shaped profile is best for your business?

Aluminum alloys used in l-shaped aluminum profiles

Profall manufactures its extruded products using selected aluminum alloys from the 1000, 3000, and 6000 series, each chosen for its specific technical and mechanical properties:

- 1000 series: these nearly pure aluminum alloys (minimum 99.5%) offer excellent electrical and thermal conductivity along with high corrosion resistance, making them suitable for electronics and electromechanical applications.

- 3000 series: manganese-based alloys in this series provide enhanced mechanical strength and corrosion resistance. They are commonly used in the automotive industry, heat exchangers, and building construction.

- 6000 series: containing silicon and magnesium, these alloys deliver a well-balanced mix of strength, weldability, and workability. They are ideal for structural applications and extruded components.

For the production of its L shaped aluminum profiles, Profall primarily uses aluminium alloys 1050, 1070, 3103, and 6060. These materials are selected to ensure that every aluminum L profile, L shaped aluminum bar, or L shaped aluminum extrusion delivers the durability, strength, and precision required by industries such as electronics, technical furniture, lighting, automotive, and electromechanics.

Profall’s customization service

In case you’re looking for a specific L-shaped aluminum profile, with unique technical and mechanical specifications, you can ask for Profall’s support. Our engineering team can create customized extrusions for your needs!

The customization process includes the following:

- the receipt of a technical drawing where the required properties of the L-shaped aluminum profiles are specified

- the feasibility analysis, the prototyping of the piece, and its pre-series production

- finally, the finished product delivery no matter where you are in the world

With our customization service, you can obtain profiles with specific shapes, sizes, colors, and dimensional tolerances. You can also ask for the following special processing

- cutting to size

- drilling and micro drilling

- shearing

- milling

- CNC machining

- bending

- calendering

- anodizing

- RAL painting

The versatility of aluminum corners

Thanks to their simple yet functional geometry, L shaped aluminum profiles are used across a wide range of industries. Their adaptability, structural integrity, and aesthetic value make them suitable for both technical and decorative applications.

The main sectors that benefit from these profiles include:

- Electronics and electromechanics: used as support structures, casing elements, or corner protectors due to their conductivity, light weight, and corrosion resistance.

- Technical furniture and interior design: their clean, modern look and easy customizability make aluminum L profiles ideal for shelves, cabinets, workstations, and modular systems.

- Lighting industry: integrated into lighting fixtures and LED systems, L shaped aluminum bars offer stability and efficient heat dissipation.

- Automotive and transportation: employed in panels, reinforcements, and brackets where lightweight materials with structural performance are essential.

- Construction and architecture: widely used in frames, cladding, and trims, L shaped aluminum extrusions provide both structural support and design precision.

This wide range of applications confirms the versatility of aluminum corners as indispensable components in both industrial and design-oriented projects.

Where can I find the right L-shaped aluminum profile? On Profall’s website!

Profall is a leading company in the field of aluminum extrusions on the Italian and international market for many years, knows the needs of its customers, and is daily engaged in the development of high-technology aluminum extrusions.

Here’s what we guarantee:

- a collaborative approach, with the aim of solving all customer needs. We are able to analyze every technical requirement, even the most complex, coming into contact with different realities

- the best technical support from the beginning, studying the best solution with the customer already in the design phase

- fast deliveries and consistent and complete answers from a technical point of view. The company is organized to guarantee short lead times. Prototyping and pre-series production take place, on average, in 3 weeks. The subsequent production takes place in just 2 weeks

- highly customizable and custom L-shaped aluminum profiles. By specifying the required production quantity and providing a general outline of the profile, we are able to give you a quick quote

- a safe and ecological production cycle, respecting the environment and the most stringent European regulatory standards

- the 850-ton extrusion and press line which guarantees the production of high-quality extrusions, even very small ones, and that not all companies are able to do.

Try the best L-shaped aluminum profile for you

Tags:

Aluminum profileMay 14, 2025 10:00:00 AM