In this article, we will delve into:

Profall’s sliding door aluminum profiles

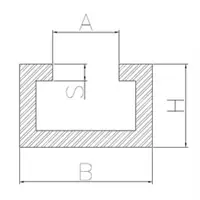

T-tracks

Aluminum T-tracks are fundamental extrusions in the building and furnishing industries. They are made by resorting to the qualities of the best aluminum alloys, specifically the 1050, 1070, 3103, and 6060.

Since these are standard profiles, they present a simple shape and size, and their dimensional tolerance equals +/- 0.15mm. According to your needs, they can be customized with special sizes and characteristics and can be demanded with a minimum order quantity of 300 kg.

These aluminum extrusions are perfect to be used in the mounting of sliding doors because they serve as tracks in which you can insert the component allowing for the door to delicately slide in one direction or another.

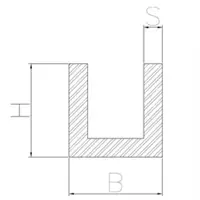

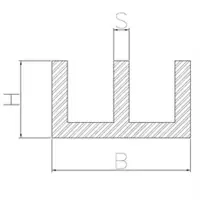

U-channels and double ducts

Aluminum U-channel extrusions and aluminum double duct profiles are also standard extruded tracks with a dimensional tolerance of +/- 0.15mm. They are manufactured by resorting to the qualities of the best aluminum alloys, specifically the 1050, 1070, 3103, and 6060.

The difference between these two aluminum profiles for sliding doors lies in the number of extruded tracks they are equipped with. As their name implies, U-channels are U-shaped, thus they offer a single track. On the other hand, double ducts have double tracks.

Always used in the building and furnishing fields – even the technical ones –, these profiles can be customized according to the customer’s needs. They can be demanded with a minimum order quantity of 300 kg.

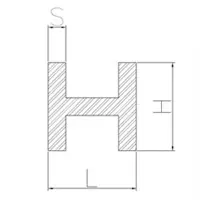

H-sections

Aluminum H-sections, instead, similarly to double ducts, present double extruded tracks that are not aligned side by side but one mirrors the other, and this creates the characteristic H shape.

These standard extrusions are made by resorting to the qualities of the best aluminum alloys, specifically the 1050, 1070, 3103, and 6060, and present a dimensional tolerance of +/- 0.15mm. They can be demanded with a minimum order quantity of 300 kg.

They are perfect as sliding door aluminum extrusions thanks to their double extruded track, which makes them ideal to host sliding partitions in ships and other types of boats, for example.

Glazing extrusions

Finally, among the special profiles in our catalog, you can also find aluminum glazing extrusions, which are particularly suitable for assembling and mounting sliding glass doors and partitions.

These products are made by resorting to the natural qualities of the 6060 aluminum alloy, which is composed of aluminum, magnesium, and silicon. This alloy is suited to be used for applications with high technical complexity and for decorative purposes, both in interiors and exteriors, such as in the case of thin sliding doors.

They can be demanded with a minimum order quantity of 300 kg and are available in different sizes and configurations in order to meet the diverse requirements of our customers.

Why don’t you take a look at our entire catalog?

Each and every application field of these profiles

As we have mentioned earlier, our extruded aluminum sliding door tracks find widespread use mainly in the interior design and furnishing (even technical) fields but also for external applications since they’re resistant to atmospheric agents.

They play an important role even in the automotive and transportation fields when it comes to building vehicle doors with slide openings, for example.

An honorable mention goes to the marine and naval fields, where the extruded aluminum we use to manufacture our tracks are more than ideal for the assembly of sliding doors in ships.

Profall, in fact, collaborated on the installation of MSC Crociere’s internal cabins. The cruise company relied on our incredible finished extrusions to assemble aluminum sliding doors and other internal components of its ships.

Characteristics of sliding door extrusions

Now, let’s delve into the characteristics that make aluminum extrusions – specifically those manufactured by Profall – perfect for sliding doors and partitions, both in the marine and other fields:

- lightness, the essential quality of aluminum, whose weight is incredibly lower than steel, and this makes it easy to install

- resistance to different factors: not only external agents but also corrosion, thermal stress, and shocks and scratches

- long service life, which is due to the fact that aluminum is a solid and robust material, thus even the sliding doors that resort to its properties will last longer

- sustainability, because the production of aluminum has a lower impact on the environment and, once its life cycle ends, it can be recycled

- compatibility with several surface treatments, among which there are anodizing and painting, in order to give the sliding door aluminum profile a unique esthetic appearance and improve its qualities

Once installed on sliding doors and partitions, our aluminum extruded tracks guarantee a silent functioning and can be used with other different materials, thanks to their strong versatility in endless situations.

Rely now on our sliding door extrusions for your applications!

Tags:

Aluminum profileApr 5, 2023 12:00:00 AM