Profall is a reliable international partner for the supply of aluminum extrusion profiles in standard and special shapes.

In this article, you will learn more about:

- Profall's expertise in small-dimensioned aluminum profiles

- Aluminum profile extrusions by Profall

- What is aluminum profile extrusion?

- Fields of use

- Choose Profall aluminum profile extrusion

Mastering the art of extrusion: Profall's expertise in small-dimensioned aluminum profiles

In the industrial realm, precision in component production is paramount, especially when it comes to intricate details and constrained sizes. Profall, a leading company in the aluminum processing sector, is renowned for its craftsmanship and expertise in providing solutions that meet these demands. Our specialization doesn't merely rest in producing aluminum profiles but extends to that niche of manufacturing many shy away from due to its complexity: ultra-thin and small dimensioned profiles.

The challenge in creating these unique profiles mainly lies in the ability to uphold high-quality standards while operating on incredibly tight tolerances. Profall has successfully navigated this challenge, marrying engineering artistry with the latest extrusion technologies. This has positioned them as a benchmark in the industry for precision aluminum profile production.

Beyond the technical challenges, producing small-sized aluminum profiles requires significant attention to detail at every production phase. Each step, from selecting the aluminum alloy, its melting, to extrusion, and quality checks, has to be executed with utmost precision to ensure the end product mirrors client expectations in terms of size, shape, and functionality. This is essential in sectors like aerospace (to create aerospace aluminum extrusions), automotive, or microelectronics, where even the slightest deviation can jeopardize the entire functioning of a system or component.

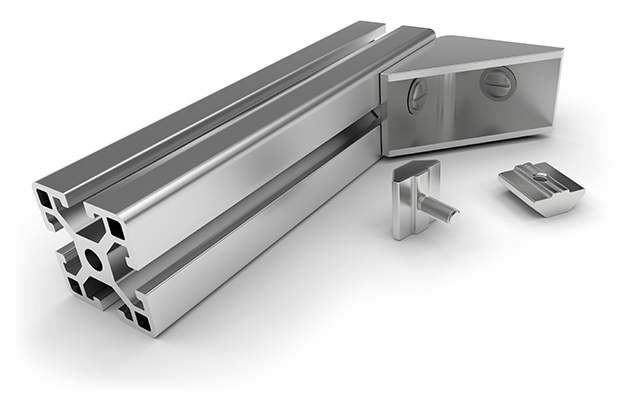

Aluminum profile extrusions by Profall

Profall creates three main types of aluminum profiles:

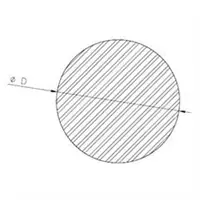

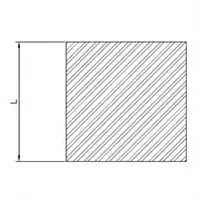

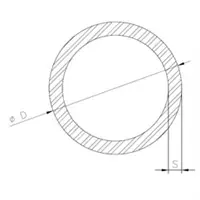

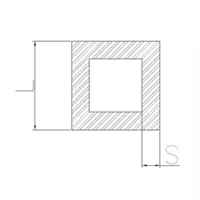

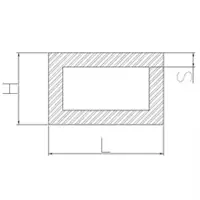

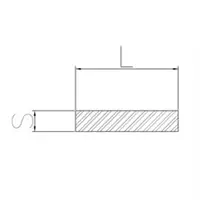

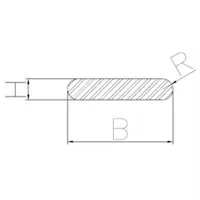

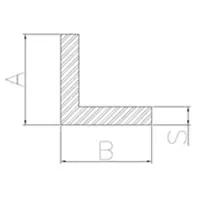

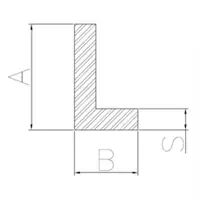

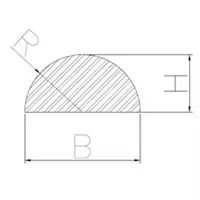

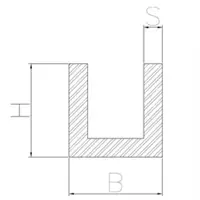

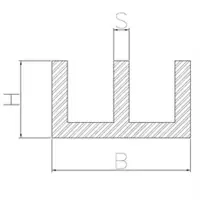

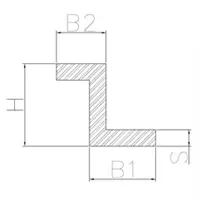

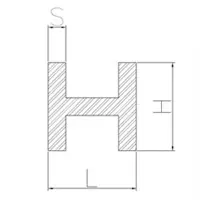

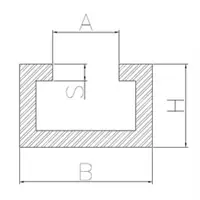

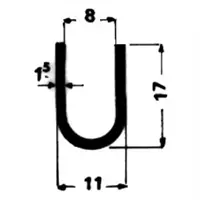

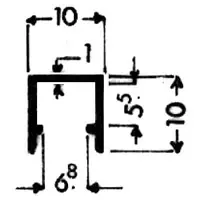

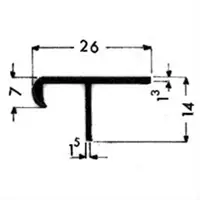

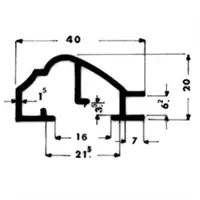

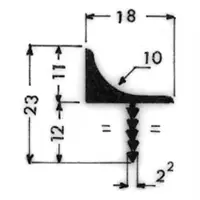

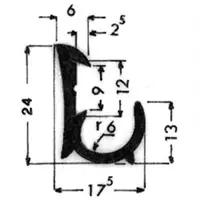

- Standard aluminum profiles: the most common include round and square bars, round, square and rectangular tubing, flat bars, U, L and H shaped aluminum extrusions.

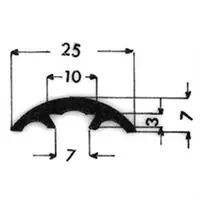

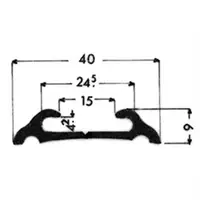

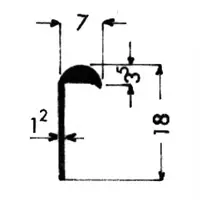

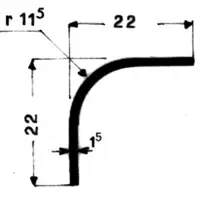

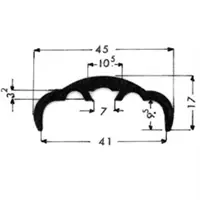

- Special aluminum profiles: this section includes complex profiles such as borders, glazing bead profiles, joint covers and tabs.

- Custom aluminum profiles: Profall is able to create fully custom-designed extruded products for specific jobs.

We answer the needs of both big industries and small ones, with a minimum quantity order starting at just 200 Kg. Technical assistance for complex requirements and fast delivery times complete our service.

Standard aluminum profiles

Standard aluminum extrusions are, by definition, aluminum profiles with simple shapes. This category includes several profiles, all of which you can browse in the listing of the products below. Here we summarize the available shapes.

Special aluminum profiles

Our special extrusions are extrusions in aluminum with specific designs.

Glazing bead profiles, borders with screw attachments, simple borders, borders for motor vehicles, transition strips with shanks, picture frames, staircase railings, furniture handles, drainers, water deflectors, curve profiles, and corner elements with special cross-sections.

Custom aluminum profiles

Profall follows the Italian tradition of aluminum extrusion to produce high quality profiles, even with thin and thinnest size that is difficult to find from the average extrusion supplier. Our technical staff is available to embrace the customer’s requirements and design the perfect, custom aluminum extrusion profile.

What is aluminum profile extrusion?

Aluminum profile extrusion is a highly efficient manufacturing process used to create intricate and customized aluminum shapes and profiles. This method involves forcing a heated aluminum billet through a shaped die to produce the desired cross-sectional profile.

Aluminum profile extrusion offers several advantages, such as lightweight and corrosion-resistant products with exceptional strength-to-weight ratios. These profiles can be tailored to meet specific design requirements, making them a preferred choice for architects, engineers, and manufacturers looking for versatile and cost-effective solutions for their projects.

Whether it's for structural framing, heat sinks, or intricate architectural designs, aluminum profile extrusion plays a pivotal role in modern manufacturing and construction processes.

Fields of use

Aluminum profile extrusion finds extensive use in a wide range of fields and industries due to its versatility and favorable properties:

- Transport: the extrusion of aluminum profiles is in great demand in the transport sector for the preparation of various types of commercial vehicles, such as buses, trains and especially boats, thanks to the special combination of lightness and strength.

- Furnishing: the extrusion of aluminum profiles is also in great demand in the furnishing sector, to create components of various kinds for furniture, flooring, fixtures, curtains and doors and windows.

- Lighting: thanks to its physical characteristics, aluminum is very suitable and required also in the lighting sector, both industrial and domestic. The extrusion of aluminum profiles is useful in the creation of profiles for LEDs, lamps or LED totems, also performing the function of dissipating the heat of the lighting element.

- Electronics: even in this sector the extrusion of aluminum profiles is very much in demand for the creation of heat sinks, as components inside photovoltaic panels and inverters.

- Electromechanics: aluminum has good electrical conductivity and, given the accessibility of this material compared to copper, it is used for the operation of electrical transformers, profiled in thin bars.

- Automotive: the components used for the air conditioning system, the radiators and the tubes for fluid distribution use aluminum profiles for their physical efficiency.

How can you use aluminum profile extrusion for your business?

Choose Profall aluminum profile extrusion

Profall is a Bergamo company expert in the extrusion of high-quality aluminum profiles. Profall is specialized in the creation of aluminum profiles, also in small and very small sizes and with high technological content. All Profall products are highly customizable and certified according to the most recent international standards.

Tags:

Aluminum profileMay 9, 2019 12:00:00 AM