In this article, we will delve into:

- Profall, aluminum window extrusion manufacturer

- Our available range of profiles

- Their manufacturing process

- Why choose aluminum window extrusions over other materials

- Energy efficiency

- The advantages of choosing Profall as your manufacturer

Profall, aluminum window extrusion manufacturer

Profilati Alluminio is a company that specializes in the extrusion and supply of aluminum profiles for several industries. Among these, the construction field is included, for which we manufacture aluminum window extrusions, as well as other solutions for frames.

Thanks to our internal processes – which are characterized by accurate and high-quality treatments – we can offer a catalog that includes standard, special, and even customized solutions, as to meet our clients’ needs in any way.

Relying on Profall means counting on the manufacturing of resistant and versatile window extrusions made starting from the best aluminum alloys available – such as the 1050, 1070, 3103, and 6060. Furthermore, each one of our products is certified according to European standards in terms of security.

The range of aluminum window extrusions we manufacture

Corner extrusions with even sides, uneven sides, and special cross-sections

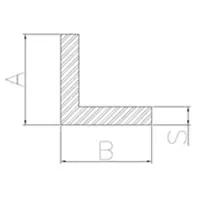

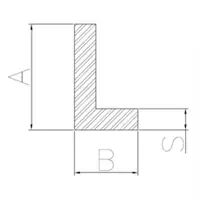

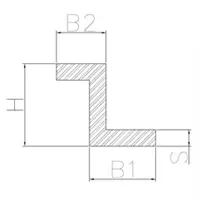

Aluminum corner profiles are crucial elements in the manufacturing of windows. In our catalog, you will find three types:

- Corner extrusions with even sides

- Corner extrusions with uneven sides

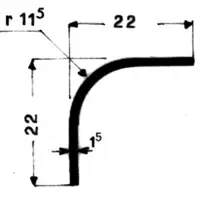

- Corner elements with special cross-sections

Corner extrusions with even and uneven sides are profiles with a distinctive L shape. They differ for the side length, which is different. These are standard profiles, which are made in simple shapes and with a dimensional tolerance of +/- 0.15mm on the side.

They are mainly used in the electronic, furnishing, robotic, construction, mechanical, electromechanical, and domestic fields.

Corner elements with special cross-sections, instead, are aluminum extrusions for windows that are manufactured in a special configuration, not only in the construction field but also to assemble industrial vehicles, where they are used as essential components for windows.

They are made in the 6060 aluminum alloy which gives them high mechanical strength, and thermal and electrical conductivity and makes them compatible with treatments such as welding.

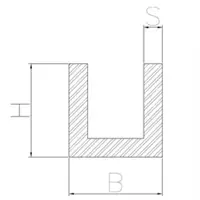

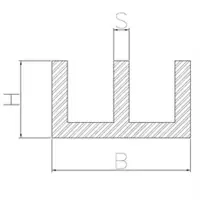

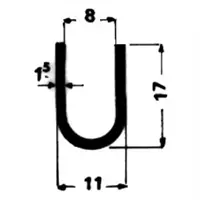

U channels, double ducts, and special U profiles

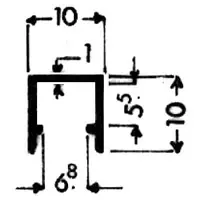

Among the most fundamental aluminum profiles for window manufacturing, you will find all those extrusions that support the sliding, so that opening and closing the window is a safe and gentle operation. We’re talking about:

U channels and double ducts are standard profiles that differ in the number of tracks they host. They present dimensional tolerances of +/- 0.15mm on the side and find use in the electronic, electromechanical, automotive, furnishing, construction, and domestic fields.

Special U channels, instead, present a more rounded shape than the others, because they’re aluminum profiles that can adapt to windows with special configurations, not only in the construction field but also to assemble industrial vehicles.

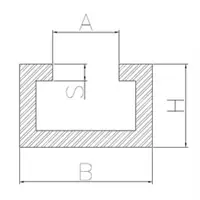

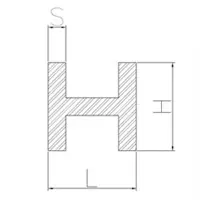

T-tracks, H sections, and Z bars

Three standard extrusions in our catalog find widespread use in the manufacturing of aluminum windows. Here they are:

Aluminum T-tracks, also known as C profiles, are similar to U channels but have a more distinguishing shape. They serve as a supporting element for the safe and efficient sliding of windows.

H sections, instead, can be used as sliding elements thanks to their mirrored double tracks. Other applications of these extrusions are as window uprights or junction elements.

Finally, Z bars are mainly used to manufacture aluminum window frames and structures with increased load-bearing capacity. They are also employed to permanently fix the window glass.

All these profiles present dimensional tolerances of +/- 0.15mm on the side and find use in the mechanical, electronic, construction, domestic, automotive, and furnishing fields.

Glazing extrusions and picture frames

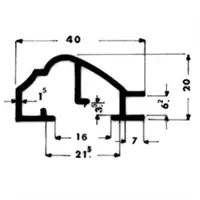

Finally, there are two other types of aluminum extrusions used in window manufacturing, this time they belong to the special profile category. Here they are:

Glazing extrusions are fundamental in the construction and furnishing industries. These are profiles designed to host and fix the glass to the window frame. They can be assembled into the structure through coupling or interlocking.

Picture frames, instead, are composed of a base element for wall fixing and a snap closure element for window glass fixing. These profiles have a 45° cut and can host fastening and corner assembly brackets.

Discover our full catalog!

Customized profiles

Among the services offered by Profall, there’s also the possibility to ask for customized extrusions. In fact, if the products in our catalog don’t meet your requirements, we can manufacture the one that meets the technical and mechanical characteristics you’re looking for.

As customized aluminum window extrusion manufacturers, we offer a simple procedure: you only need to send us the technical drawing of the piece and we’ll test the project's feasibility, start its prototyping and, consequently, carry out its pre-series production.

Customization happens in terms of:

- shapes, colors, sizes, and dimensional tolerances

- mechanical treatments (such as drilling, shearing, and CNC machining)

- surface finishes (such as anodizing and RAL painting)

The manufacturing process of aluminum extrusions

The manufacturing process of aluminum profiles – both for windows and other applications – can vary according to the extrusion method used. Generally, it includes the following steps:

- First, aluminum is prepared for extrusion through melting, thus skilled into a matrix with the desired shape – heat makes it more malleable

- Melted aluminum is then inserted into a press, where it is pushed on the other side of the matrix through direct or indirect extrusions, to give it the required shape

- Once extracted from the press, the extrusion is left to cool rapidly– as to avoid possible deformations – and is later cut into the desired length

This is how Profall manufactures aluminum window extrusions.

Why choose aluminum window extrusions over other materials

When comparing materials used for window and door frames—such as PVC, wood, and steel—aluminum stands out as the most advanced solution in both industrial and architectural applications. Its physical and mechanical properties make it ideal for projects that require high performance, aesthetics, and durability.

The main advantages of aluminum compared to other materials:

Durability and structural strength

Aluminum resists corrosion, humidity, and UV rays, maintaining its mechanical properties even after years of exposure. Unlike wood, it does not warp and does not require frequent treatments.

Low maintenance

It is easy to clean, does not crack, swell, or fade over time, drastically reducing management and maintenance costs.

Lightweight and easy installation

Its low density (2.70 g/cm³) makes it significantly lighter than steel, simplifying the handling and assembly of window frames.

Design precision and versatility

Profiles can be extruded into complex shapes with extremely precise tolerances, making them ideal for custom projects and modern architecture.

Sustainability

Aluminum is infinitely recyclable without losing quality. This makes it an excellent choice for projects that follow environmental sustainability criteria (e.g., LEED or BREEAM certifications).

Energy efficiency: how aluminum extrusions improve window performance

One of the most common misconceptions about aluminum concerns its thermal conductivity, historically higher than that of plastic or wooden materials. However, modern extrusion and design technologies have revolutionized the thermal behavior of aluminum profiles, making them highly efficient from an energy standpoint.

Here’s how aluminum profiles contribute to energy savings:

Thermal break integrated into the profiles

Modern aluminum extrusions use insulating inserts (e.g., polyamide) to interrupt thermal bridging, significantly improving the thermal transmittance of the frames.

Use of alloys with insulating properties

Some alloys, such as 6060 alloy, offer an optimal balance between mechanical strength and moderate thermal conductivity, ideal for insulated frames.

Optimized design for insulation

Profiles designed with multiple chambers, high-performance gaskets, and shaped rebates can accommodate double or triple glazing with substantial thicknesses, also improving acoustic insulation.

Reduced energy consumption

Thanks to these technologies, the use of aluminum extrusions in windows and doors helps to:

- Reduce energy demand for heating and cooling

- Improve the building’s energy rating

- Comply with regulations such as EU Directive 2010/31/EU on energy efficiency

Today, aluminum is a material that combines aesthetics, strength, and energy performance, in line with the requirements of modern low-impact buildings.

The advantages of choosing Profall as your manufacturer

As well as benefiting from a vast catalog of solutions and our customization service. Relying on Profall for the manufacturing and supplying of window aluminum extrusions means counting on a skilled and professional company in each step of our processes.

Not only will we walk you through the manufacturing of the window aluminum extrusion you’re looking for, helping you create the product that best suits your application needs, but we also offer:

- 2 working weeks worldwide delivery, thanks to our international delivery service

- after-sales assistance for every need

The efficiency of our service is renowned by all our worldwide clients, who can find in our products the solution they need.

Start relying on Profall’s know-how!

Tags:

Aluminum profileOct 22, 2025 8:37:00 AM