Including aluminum in all industries is a clear sign that this material is slowly replacing its competitors due to its globally recognized quality.

Its malleability is certainly one of its key features since it can be reduced into thin strips without altering its properties. Profall creates various sized flat aluminum bars, intended for a myriad of uses.

Which aluminum bars should you choose

Flat extruded aluminum bars are not all the same. You have a wide range of sizes and different alloys according to the work to be done.

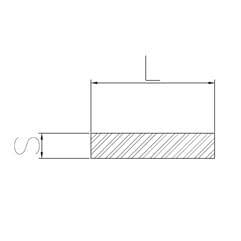

Profall flat aluminum bars are widely used in almost all industries. These are classic flat, rectangular-sectioned bars, created with 1050, 1070, 3103, and 6060 alloys. Due to the advanced engineering department, Profall is also able to create small and extremely small sized flat extruded aluminum bars with a minimum of 5 mm and a maximum of 120 mm thickness.

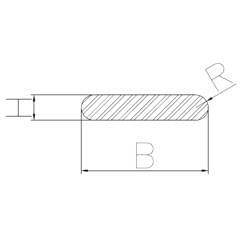

Rounded edge flat aluminum bars

Especially used in electromechanics to create electrical transformers, rounded edge flat extruded aluminum bars also 5 mm to 120 mm thick are made with +/- 0,15 mm standard dimensional tolerance on the side. These bars can be wound on a minimum of 500 kg coils.

The advantages of flat aluminum bars

This material has quickly spread to almost all industrial sectors. In particular, flat extruded aluminum bars are used in the furniture, construction, and mechanical industries but their versatility continues to reap success in many other contexts.

- With simple periodic surface cleaning, flat aluminum bars do not require maintenance.

- Aluminum is easy to process and can be used to achieve profiles of any type for any type of process.

- Aluminum is a lightweight material despite its high resistance.

- Thanks to the ability to support various specific processes, aluminum has excellent weather resistance.

- Aluminum is malleable and ductile, in addition to having various other mechanical properties that make is suitable for a myriad of industrial processes.

- It can be said that flat aluminum bars are ecological and eco-sustainable since they are 100% recyclable.

Due to its 850 ton press and extrusion line and up to date machine pool, Profall is a company also able to produce extremely complex extruded aluminum parts that not everyone can manufacture.

Why choose Profall flat extruded aluminum bars

Profall guarantees quality and experience. The company from Bergamo has been operating in the extruded aluminum industry for many years and is able to create even extremely small flat aluminum bars and highly complex custom profiles, facing any type of technical aspect without any problem.

- Continuous investments in research and development.

- Specialized in the production of precise and complex profiles.

- One of a kind experience and skills in this sector.

- High customization.

- Fast deliveries and guaranteed support.

- Small supply lots also available.

Tags:

Aluminum profileNov 14, 2018 12:00:00 AM