The high availability and low cost of this material have made most of the metals in circulation obsolete. Profall is able to manufacture high quality aluminum tubing, of different shapes and sizes depending on the job for which it is required.

The advantages of aluminum tubing

Aluminum tubing has mechanical properties that make it unique. Why choose aluminum over other materials?

- Aluminum tubing offers a greater volume of product for purchased weight much higher than steel, this translates into obvious advantages from the point of view of mobility.

- Aluminum tubing does not tarnish and is more prone to being painted.

- Aluminum tubing offers considerable strength and durability.

- Aluminum tubing is an excellent heat conductor.

- Aluminum tubing is easily weldable and corrosion resistant.

Aluminum tubing for each sector

Mechanics, electromechanics, automotive, aircraft

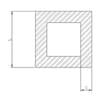

We generally recommend our square tubing for these particular sectors.

Profilati Alluminio square tubing is extruded aluminum tubing made of soft alloys, certified and compliant with current European regulations.

It is also possible to choose between bar or roll formats starting from the size of 7 mm. Aluminum square tubing can be ordered in minimum quantities of 300 kg for the bar format and 500 kg for the roll format.

Construction and furnishing

The most popular aluminum tubing for these precise sectors is definitely our round tubing.

The most popular aluminum tubing for these precise sectors is definitely our round tubing.

We produce round aluminum tubing with a minimum diameter of 5 mm and a maximum diameter of 120 mm, but we are able to manufacture extruded tubing with tolerances and special mechanical characteristics upon request. Generally, extruded round tubing has dimensional tolerances of +/- 0.15 mm in diameter. They can also be used in the mechanical and electromechanical sectors.

Other industrial sectors

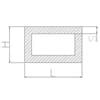

The most versatile Profilati Alluminio products, and therefore used by a wide range of sectors, are our rectangular tubing.

Aluminum rectangular tubing has +/- 0.15 mm standard dimensional tolerance per side. Supplied in bar or roll tubing versions. The minimum quantities are 300 kg for the bar format and 500 kg for the roll format.

Aluminum rectangular tubing has +/- 0.15 mm standard dimensional tolerance per side. Supplied in bar or roll tubing versions. The minimum quantities are 300 kg for the bar format and 500 kg for the roll format.

Made of 1050, 1070, 3103, and 6060 aluminum alloys, aluminum rectangular tubing is used in the construction, furnishing, electromechanical and mechanical sectors, but adapt to any industrial sector (aerospace aluminum extrusions, for instance, are increasing in demand).

Which aluminum tubing is best for your business?

Tags:

Aluminum profileSep 6, 2019 12:00:00 AM