In this article we will delve into:

- Profall’s square extruded aluminum

- The extrusion process of square aluminum

- Applications and advantages

- Profall’s customization possibilities

Profall’s square extruded aluminum profiles

Profall manufactures high-quality square aluminum extrusions. In our catalog, you will find two types of these profiles. They both belong to the standard profile category. Let’s see what we’re talking about:

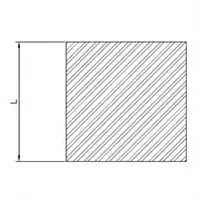

Square bars

Profall’s aluminum square bars are made with square-section aluminum extrusion. Their weight ranges from 43 to 1060 grams. Their dimensional tolerances are equal to +/- 0.15mm on the side, but they can be customized according to the customer’s needs.

Their production process includes the use of the 1050, 1070, 3103, and 6060 aluminum alloys and compliance with the current European laws in terms of security.

This type of square extruded aluminum finds widespread use in the mechanical, electromechanical, and furnishing fields and can be supplied both in the bar format (from a minimum order quantity of 300 kg) and the reel format (500 kg minimum).

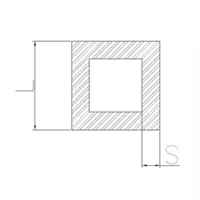

Square pipes

On the other hand, our aluminum square tubings are made with square-section aluminum extrusion but, compared to our bars, are hollow. Their dimensional tolerances are equal to +/- 0.15mm on the side, but they can be customized according to the customer’s needs.

Their production process includes the use of the 1050, 1070, 3103, and 6060 aluminum alloys and compliance with the current European laws in terms of security.

This type of square extruded aluminum finds widespread use in the mechanical, electromechanical, automotive, and furnishing fields and can be supplied both in the bar format (from a minimum order quantity of 300 kg) and the reel format (500 kg minimum).

Do you want to know more about our square aluminum extrusions?

The extrusion process of square aluminum

When we talk about extrusion, we refer to a specific aluminum treatment. Using a high-pressure press machine, a piece of aluminum obtains the desired shape – in our case, square.

What are the steps of square aluminum extrusion?

- Aluminum is heated to high temperatures so that it can be molded more easily into the required shape

- The molten piece is inserted into the press and strongly compressed into a matrix with the desired shape of the profile needed – thus, square

- The result is a square extruded aluminum profile that must be cooled so that it maintains its mechanical properties

There are two ways to obtain square aluminum extrusions:

- through direct extrusion, when the metal is pushed into the matrix from the press head. This is ideal for profiles with simple geometries.

- through indirect extrusion, where, on the other hand, aluminum is compressed on the opposite side, from the bottom of the matrix. This is ideal for profiles with more complex geometries.

What are their applications and why?

As we have mentioned before, our square extruded aluminum profiles find widespread use mainly in the mechanical, electromechanical, automotive, and furnishing sectors. Their uses are not limited to these, though.

We can list the applications of these extrusions as follows:

- the creation of metal structures in the construction field

- the production of car frames and structural parts

- components for electrical heat sinks

- components for navy and aerospatial vehicles

- the production of furniture and structures for interiors

The reasons why these square aluminum extrusions are versatile are mainly linked to their lightness – since aluminum is consistently lighter than steel, for example – and their resistance – to corrosion, shocks, and shear.

Let alone that this metal is compatible with several surface treatments and finishes that can improve its technical and mechanical features. Here at Profall, we can help you customize the product you’re looking for.

Profall’s customization possibilities

Profilati Alluminio is a company specializing not only in the extrusion of aluminum profiles – even square-shaped – but also in the customization of a product that, because of its complexity, it’s hard to find on the market.

The customization we offer concerns:

- the creation of square aluminum extrusions in specific shapes, sizes, and dimensional tolerances

- the implementation of specific treatments such as cuttings to size, drilling, shearing, milling, CNC machining, and bending

- the possibility to add surface finishes such as anodization and RAL painting, to improve the piece’s protection and give it a unique esthetical appearance

To ask us for square extruded aluminum, you only need to send us a technical drawing that includes all the characteristics you look for. Our engineering team will proceed to test its feasibility and consequently will carry out the prototyping and pre-series production of the piece.

Finally, thanks to our international delivery service, we can supply you with your order in 2 working weeks only, no matter where you are in the world. And for any other need, we have specific technical support you can contact.

Ask now for your square extruded aluminum supply!

Tags:

Aluminum profileAug 2, 2023 12:00:00 AM