At Profall, we don’t just supply standard profiles — we create tailored aluminum solutions for high-performance industries.

Modular aluminum extrusions are in high demand across multiple industries due to their ease of application, structural versatility, and durability—even in the most complex assemblies. These profiles allow for efficient integration, customization, and long-term reliability in various technical environments.

In this article, you will discover:

- Profall’s modular aluminum profiles

- What are modular aluminum profiles

- Applications of modular aluminum extrusions

- Profall’s full service approach

Profall’s range of modular aluminum extrusions

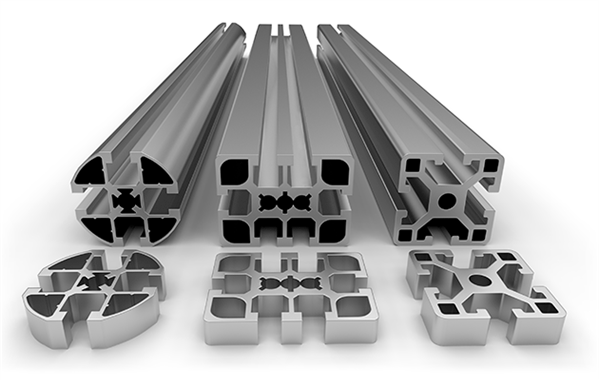

Leveraging our advanced know-how and manufacturing capabilities, Profall designs and produces a wide variety of modular aluminum extrusions, grouped into two main categories:

Standard modular aluminum extrusions

Standard aluminum extrusion profiles are modular components engineered in conventional shapes and sizes to meet industrial requirements. Manufactured using top-grade aluminum alloys, they ensure precise technical and mechanical performance.

Profall’s standard modular profiles feature dimensional tolerances of ±0.15 mm and include the following solutions:

Special modular aluminum extrusions

In addition to standard options, Profall manufactures special modular aluminum extrusions designed for advanced technical and mechanical requirements. These profiles feature unique shapes, custom dimensions, and are often unavailable through conventional suppliers.

Thanks to the high precision and technological sophistication of our production processes, we can also deliver ultra-thin and highly complex geometries with exceptional accuracy.

Our range of special modular profiles includes:

Are you looking for modular aluminum extrusions?

Modular aluminum extrusions: what they are and why choose them

Modular aluminum extrusions are engineered profiles created with standardized dimensions and repeatable cross-sections that simplify assembly and integration. Built on the principle of modularity, these extrusions can be combined to create more complex structures without extensive machining or tooling.

Designed for industries requiring quick installation, structural adaptability, and long-lasting performance, modular aluminum profiles provide:

- fast and easy installation

- minimal need for mechanical processing

- high flexibility and integration

- excellent corrosion resistance

- lightweight strength

- customizability

Whether you require standard or special shapes, Profall delivers high-precision modular aluminum extrusion solutions. Our use of high-quality alloys, such as 6060, ensures performance even in harsh environments, including marine, transport, and electronic sectors.

Applications of modular aluminum extrusions

Thanks to their structural versatility, ease of assembly, and excellent resistance to external agents, Profall’s modular aluminum extrusions are used in a wide range of sectors. Whether in standard or custom configurations, they ensure performance, adaptability, and precision in demanding environments.

Automotive

Used for trim profiles, internal framing, and lightweight structural components, our modular extrusions contribute to reducing vehicle weight while ensuring mechanical strength and corrosion resistance.

Electronics

Modular profiles provide protective enclosures, heat-dissipating structures, and support frames for electronic devices and systems, where precision and thermal performance are key.

Lighting

Perfect for mounting systems, linear lighting profiles, and structural holders, modular aluminum extrusions allow for seamless integration in architectural or industrial lighting solutions.

Furniture & Interior Design

Our extrusions are widely used in furnishing and design contexts as handles, decorative trims, edging systems, and connectors — combining aesthetics with durability.

Construction & Architecture

Glazing systems, transition strips, corner protections, and handrails benefit from the strength, customization, and clean finish of Profall's modular profiles.

Marine & Offshore

Aluminum alloys like 6060, used in our modular extrusions, are particularly suited for marine applications, offering high resistance to saltwater corrosion, lightness, and long-term durability.

Profall’s full-service approach

At Profall, we don’t just manufacture modular aluminum extrusions—we provide a complete, end-to-end service designed to meet the most specific technical and logistical needs of your project.

Whether you need standard or custom profiles, our team supports you throughout the entire process:

Customization

We adapt the modular profiles in our catalog—or design new ones entirely—based on your technical drawings. Our engineers assess feasibility, then move to prototyping, followed by pre-series and full-scale production.

Flexible supply options

Starting from a minimum order of 200 kg, we can deliver your modular aluminum extrusions in bar or reel format, anywhere in the world. Our production and logistics network ensures delivery within just 2 working weeks, even for tailored solutions.

Unmatched precision and complexity

Thanks to advanced manufacturing capabilities, Profall achieves shapes, features, and dimensional tolerances that many competitors simply cannot match. We specialize in ultra-thin sections and technically demanding profiles.

Global after-sales support

Our relationship doesn’t end at delivery. Profall offers dedicated after-sales assistance worldwide to ensure smooth implementation and continued satisfaction.

Want to learn more about our modular aluminum profile solutions or start a project?

Tags:

Aluminum profileNov 7, 2025 10:34:02 AM

.png?width=200&height=200&name=bordure-per-autoveicoli.i544-ky5%20(1).png)

.png?width=200&height=200&name=sgocciolatoi-e-para-acqua.i556-k%20(1).png)