Here's the content you will find on this page:

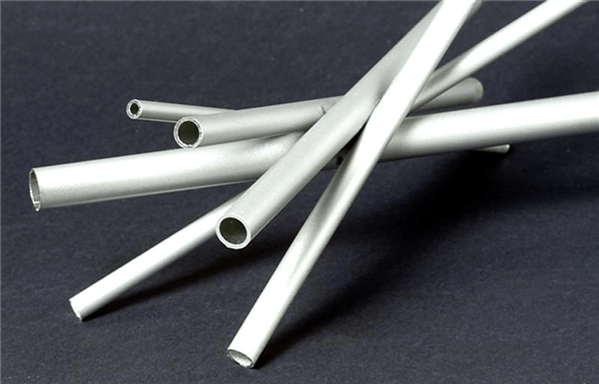

Anodized aluminum pipes by Profall

Profilati Alluminio manufactures four main types of pipe, three of which are standard and one fully customizable. Customized sizes and dimensional tolerances are also available on request for standard pipes.

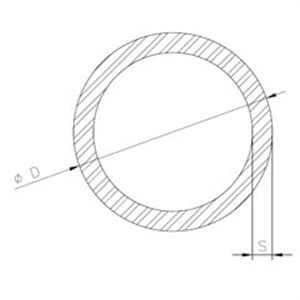

Round tubing

The alloys mostly utilized for anodized aluminum round tubing are 1050, 1070, 3103, and 6060. These pipes are employed in the mechanical, electromechanical, construction, and furnishing industries.

They can be purchased in either bar or reel format and are available in sizes that range from 5 to 120 mm. According to their format, they can be ordered with a minimum order quantity of 200 or 500 kg. In our catalog, you can find over 90 types of anodized round aluminum pipes, which differ in diameter, thickness, and weight.

Each one of our round aluminum pipes can be anodized according to your needs and is certified according to the strictest European regulations.

Take a closer look at this product:

Aluminum round tubing

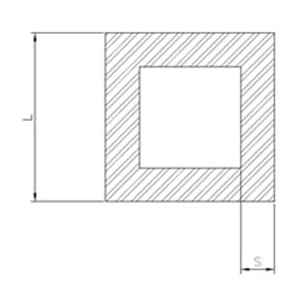

Square tubing

Generally used in the automotive, mechanical, electromechanical, and furnishing industries, square tubing is also suitable for complex applications that require specific dimensional tolerances.

These pipes are made from 1050, 1070, 3103, and 6060 aluminum alloys and are available in bar or reel format. According to this, they can be ordered with a MOQ of 200 or 500 kg. In our catalog, you can find over 20 types of anodized round aluminum pipes, which differ in side length, thickness, and weight.

Each one of our square aluminum pipes can be anodized according to your needs and is certified according to the strictest European regulations.

Take a closer look at this product:

Aluminum square tubing

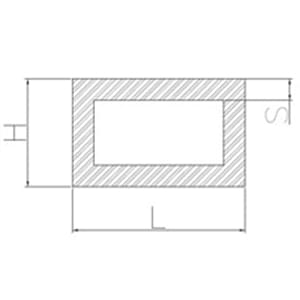

Rectangular tubing

Rectangular tubing can also go through anodizing to be used in many different sectors, mostly in the electromechanical, construction, and furnishing industries.

Available in bar or reel format, with a thickness ranging from 5 to 120 mm, they are made from 1050, 1070, 3103, and 6060 alloys. According to their format, they can be ordered with a MOQ of 200 or 500 kg. In our catalog, you can find over 25 types of anodized round aluminum pipes, which differ in side length, height, thickness, and weight.

Each one of our square aluminum pipes can be anodized according to your needs and is certified according to the strictest European regulations.

Take a closer look at this product:

Aluminum rectangular tubing

Custom anodized aluminum pipes

Fully meeting our customers’ demands is one of the flagships of Profilati Alluminio.

If you need pipes with particular shapes, sizes, and colors, specific surface treatments, or extremely low dimensional tolerances that are difficult to find on the general aluminum market, Profall is the right place for you.

One of the most requested treatments is anodizing: anodized aluminum pipes offer improved technical, mechanical, and esthetic features that make them more resistant to external agents and easily adaptable in different situations and applications.

Other types of processing and finishing we can carry out on your aluminum pipes are:

- Cutting to size

- Drilling and micro drilling

- Shearing

- Milling

- CNC machining

- Bending

- Calendering

- Coating in RAL colors (see more here: Powder coated aluminum profiles: Profall’s service)

Choose the advantages of Profall’s anodized aluminum pipes

Contact us for a free price quote

What is anodizing?

Anodizing is an electrochemical process that creates a layer of oxide on a metal surface – in this case, aluminum pipes – so that it can be used every time it is necessary to withstand adverse weather conditions or contact with different corrosive substances.

During anodizing, the surface undergoes an authentic transformation because the metal reaction to oxygen creates an external barrier made of alumina. To obtain this reaction, it’s necessary to use electric power from an external circuit (cathode), which is to be circulated in an electrolytic chamber. Here – submerged in a water solution – aluminum acts as an anode and catalyzes electric charges.

Properties and advantages of anodizing

The layer of oxide formed on aluminum pipes has a variable thickness (micron-sized). It gives the piece several properties, useful in different industrial sectors according to the type of layer.

Generally, anodizing gives the aluminum pipe a series of well-known, sought-after benefits:

- significant improvement of aluminum resistance to corrosion, protecting the pipe from a large number of chemical substances and atmospheric conditions

- increased superficial hardness of the piece, making it much more resistant to penetration

- moderate heat insulation to the piece

- improved resistance to wear and abrasion, protecting the pipe from different mechanical stresses

- protection of the piece while preserving its attractive appearance obtained through this process – the anodized aluminum pipe gains a color that can be neutral or bronze, clear or blackish.

Why choose Profall as your anodized aluminum pipe suppliers

Profall is an Italian-based technical company. It creates high-quality extrusions – including anodized aluminum pipes – even in the smallest size, with a high level of complexity and different types of surface treatments. Our team is composed of skillful professionals that are experts in this area, able to face any technical challenge to create products of proven industrial quality.

Profall is an anodized aluminum pipe supplier that guarantees unique skills in the field, developed over several years of specialized activity:

- we constantly invest in R&D activities, bringing to our sector high-quality and competitive Made in Italy expertise

- we can custom extrusions so they can perfectly adapt to your application requirements

- we are anodized aluminum pipe suppliers specialized in creating difficult, complex, precise, and highly technical products

- we accept small production batches – 200 kg or 500 kg according to format

- we guarantee short delivery terms

- we supply after-sale total support for all your needs

- we are anodized aluminum pipe suppliers with a worldwide delivery

Choose Profall’s Made in Italy quality and find out our anodized aluminum pipes!