In this article, we will delve into:

- L-shaped aluminum profiles

- Customized L-shaped aluminum profiles

- The versatility of these products

- The service Profall guarantees

L-shaped aluminum profiles: what are they?

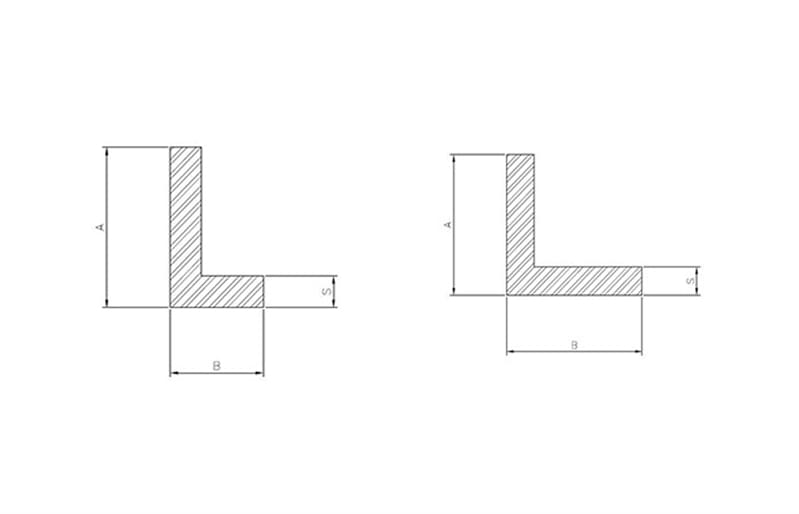

L-shaped aluminum profiles are extrusions with sides forming a 90° angle. Their sides can have the same length or a different one. Profall is able to manufacture the L-shaped profile that most suits your needs, even with a special design and small or very small dimensions.

Let’s see together the products in our catalog.

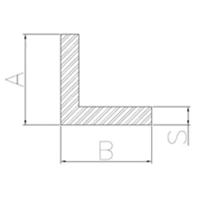

L-shaped aluminum corner extrusions with even sides

Aluminum corner extrusions with even sides are L-shaped standard profiles whose sides have the same length. They are made by resorting to the qualities offered by the following aluminum alloys: 1050, 1070, 3103, and 6060.

Thanks to their versatility, they find widespread use in the following commercial and industrial sectors:

- electronics and robotics

- furnishing – even technical

- constructions

These profiles are supplied in the bar format, with a minimum order quantity of 200 kg.

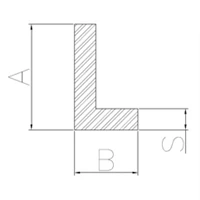

L-shaped aluminum corner extrusions with uneven sides

As opposed to these last ones, aluminum corner extrusions with uneven sides are L-shaped standard profiles whose sides differ in length. They are still made resorting to the qualities offered by the following aluminum alloys: 1050, 1070, 3103, and 6060.

Thanks to their resistance to shock, corrosion, and environmental agents, they find widespread use in the following commercial and industrial sectors:

- mechanics and electromechanics

- domestic

- constructions

These profiles are supplied in the bar format, with a minimum order quantity of 200 kg.

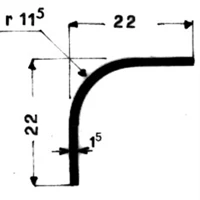

L-shaped aluminum corner extrusions with special cross section

Finally, our catalog also includes a third type of L-shaped aluminum profile – corner extrusions with special cross section. These are made resorting to the qualities offered by the 6060 aluminum alloy.

They often present a knurled surface and are mainly used as finishing elements for:

- panels

- edge elements of steps

- industrial vehicles

These L-shaped aluminum profiles are supplied in the bar format, with a minimum order quantity of 200 kg.

Which L-shaped profile is best for your business?

Profall’s customization service

In case you’re looking for a specific L-shaped aluminum profile, with unique technical and mechanical specifications, you can ask for Profall’s support. Our engineering team can create customized extrusions for your needs!

The customization process includes the following:

- the receipt of a technical drawing where the required properties of the L-shaped aluminum profiles are specified

- the feasibility analysis, the prototyping of the piece, and its pre-series production

- finally, the finished product delivery no matter where you are in the world

With our customization service, you can obtain profiles with specific shapes, sizes, colors, and dimensional tolerances. You can also ask for the following special processing

- cutting to size

- drilling and micro drilling

- shearing

- milling

- CNC machining

- bending

- calendering

- anodizing

- RAL painting

The versatility of aluminum corners

Widely used in almost all industrial sectors, an L-shaped aluminum profile is one of the most common extrusions and can even cause production difficulties that not all companies are able to manage. Profall produces high-quality aluminum corners even with high technical complexity.

Overall, aluminum angle extrusions are one of the most versatile profiles required by many industrial sectors, thanks to their wide range of uses. Of course, depending on the specific use, a profile can have numerous variants and can be made of different aluminum alloys, according to specifications that maximize its functionality on a case-by-case basis.

The L-shaped aluminum profile is also widely used in the furniture and building sector, where it is adapted to be used as a profile for all types of furniture and for windows and doors. They can be requested with different technical characteristics for each specific use.

Where can I find the right L-shaped aluminum profile? On Profall’s website!

Profall is a leading company in the field of aluminum extrusions on the Italian and international market for many years, knows the needs of its customers, and is daily engaged in the development of high-technology aluminum extrusions.

Here’s what we guarantee:

- a collaborative approach, with the aim of solving all customer needs. We are able to analyze every technical requirement, even the most complex, coming into contact with different realities

- the best technical support from the beginning, studying the best solution with the customer already in the design phase

- fast deliveries and consistent and complete answers from a technical point of view. The company is organized to guarantee short lead times. Prototyping and pre-series production take place, on average, in 3 weeks. The subsequent production takes place in just 2 weeks

- highly customizable and custom L-shaped aluminum profiles. By specifying the required production quantity and providing a general outline of the profile, we are able to give you a quick quote

- a safe and ecological production cycle, respecting the environment and the most stringent European regulatory standards

- the 850-ton extrusion and press line which guarantees the production of high-quality extrusions, even very small ones, and that not all companies are able to do.

Try the best L-shaped aluminum profile for you