In this article you will find:

- Profall’s range of aircraft aluminum extrusions

- The advantages of aerospace and aircraft aluminum extrusion profiles

- How we deliver high-quality profiles

- Why choose Profilati Alluminio

Profall’s range of aircraft aluminum extrusions

Profall’s aluminum profiles are ductile and versatile components that comply with quality, resistance, and durability standards. The high levels of technical complexity and technological innovation make our products unique and let us distinguish ourselves on the industrial scene as trusted and effective suppliers.

In fact, we manufacture specific and tailor-made aluminum profiles that respond to the needs of every industrial sector and the most complex treatment demands. Notably, we also design aerospace and aircraft aluminum extrusions – where a high degree of customization is necessary.

Profall creates a wide range of standard and special extrusions, which can be customized according to your most specific needs. The most demanded aluminum extrusions for aerospace and aircraft are:

- bars

- tubing

- semicircular elements

- U channels

- Z bars

- H sections

- T-tracks

Aluminum flat bar

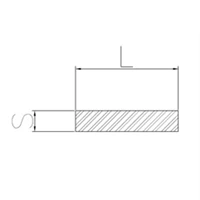

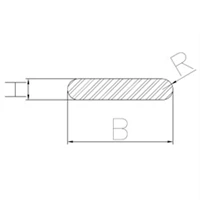

Aluminum flat bar Aluminum flat bars with rounded edges

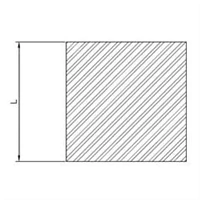

Aluminum flat bars with rounded edges Aluminum square bar

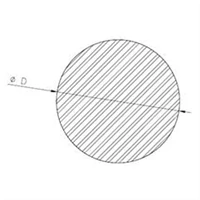

Aluminum square bar Aluminum round bar

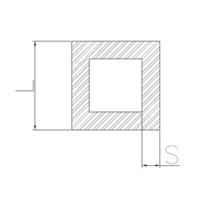

Aluminum round bar Aluminum square tubing

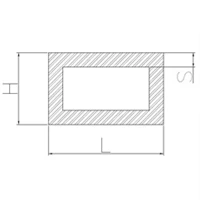

Aluminum square tubing Aluminum rectangular tubing

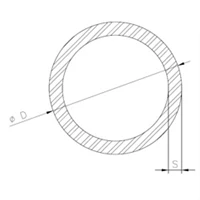

Aluminum rectangular tubing Aluminum round tubing

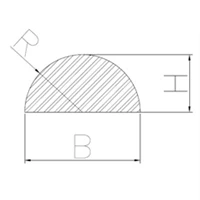

Aluminum round tubing Aluminum semicircular elements

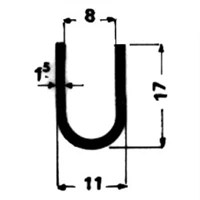

Aluminum semicircular elements Special U-profiles

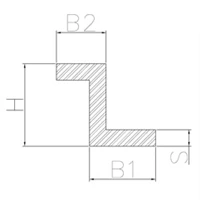

Special U-profiles Aluminum Z bar

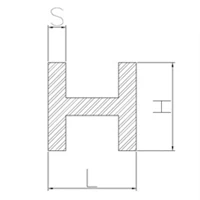

Aluminum Z bar Aluminum H section

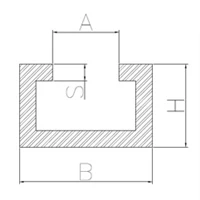

Aluminum H section Aluminum T-track

Aluminum T-track

The advantages of aerospace and aircraft aluminum extrusion profiles

In a field where lightness and durability are essential, the aerospace and aircraft aluminum extrusions we manufacture guarantee a reduction of overall vehicle weight, high solidity, and affordable prices.

Aircraft and aerospace are largely using these metal alloys, especially large-scale aluminum extrusions, because they:

- are highly versatile and suitable for different types of vehicles

- are highly resistant and easy to work

- are light and thin

- provide high precision for dimensions and finishes

- offer great performances and best quality

Profall manufactures aluminum structural components and special housings for cockpit electronics and special components for airplanes, helicopters, and launch vehicles. Among the application examples of our aerospace and aircraft aluminum extrusions we find:

- beams, keels, crosspieces, and longerons

- cockpits

- rotating parts of helicopters in the shape of hollow beams

- landing gears, fuselages, tails

- fuel tanks

How we deliver high-quality profiles

To ensure the highest quality and precision in the production of aluminum profiles for the aerospace and aircraft industries, Profilati Alluminio uses advanced extrusion techniques.

One such technique is the compression of a cylindrical aluminum solid block by a horizontal press in such a way that it is forced through one or more holes in the matrix.

We also use strict quality controls throughout the production process. This means that each extruded profile is thoroughly tested to verify its compliance with the specifications required by the customer. These quality checks include visual inspections, dimensional checks, tensile strength tests and corrosion tests.

Finally, we also use finishing techniques to ensure that the profiles meet customer-specific requirements. These techniques may include cutting, milling, drilling, sanding, and polishing, which result in profiles with smooth, uniform surfaces.

Profall’s advantages: why choose us

Profall’s main advantage is to supply you with aluminum profiles that are completely functional – since they are 100% customized according to shapes, dimensions, and finishings, according to your application needs.

But that’s not it: Profall guarantees numerous advantages, such as:

- the possibility to order small batches of aluminum profiles – generally starting from 200 kg

- the guarantee of a rapid delivery in about 2 weeks and lower costs which is valid for worldwide shipments

- after-sale technical support wherever you are

- immediate response to every customization demand or requirement, to adapt your extrusions to your needs

Are you looking for aerospace and aircraft aluminum extrusions?