Aluminum profiles are one of the most common processes using this metal, obtained through extrusion. In fact, the functionality and advantages of aluminum in the industry field have been known for more than a century, and its characteristics offer it a wide application in countless sectors.

Aluminum bars manufactured by Profall

Thanks to our know-how and cutting-edge machinery – which also includes 850 ton presses and extrusion lines – Profall can meet any demand and suggest the most suitable extruded for you.

We manufacture five types of extruded aluminum bars, four of which are standard and one fully customizable according to your needs. Custom sizes, dimensional tolerances, and surface finishes are also available for standard bars.

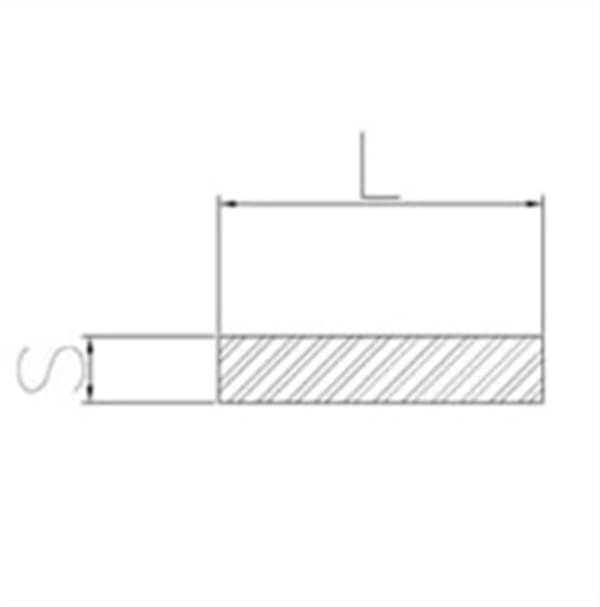

#1 Flat bars

Flat bars are employed in various sectors, such as mechanical, furnishing, electromechanical, and construction.

Flat bars are employed in various sectors, such as mechanical, furnishing, electromechanical, and construction.

Profall can manufacture aluminum profiles even in the smallest size, creating flat aluminum bars with a minimum width of 5 mm and a maximum of 120 mm.

The main alloys utilized are 1050, 1070, 3103, and 6060.

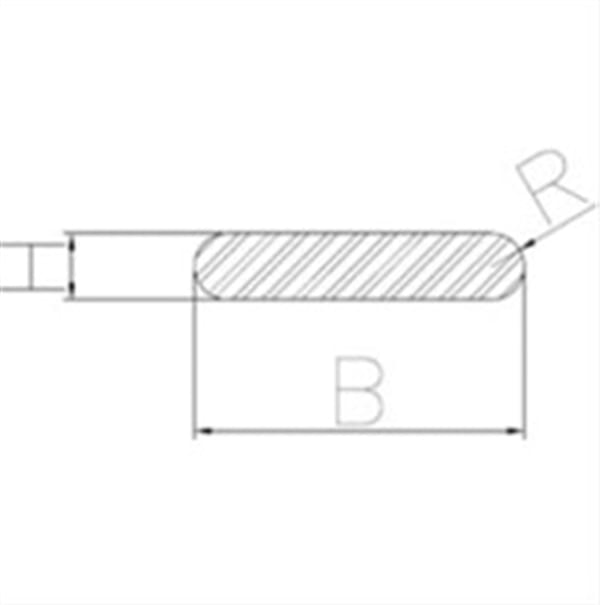

#2 Flat bars with rounded edges

Aluminum flat bars with rounded edges are used primarily in the electromechanical sector, especially for building electrical transformers.

Aluminum flat bars with rounded edges are used primarily in the electromechanical sector, especially for building electrical transformers.

These extruded aluminum bars have standard dimensional tolerances of +/- 0,15 mm per side, thicknesses ranging from 5 to 120 mm, and can be purchased in reel format with a minimum order quantity of 500 kg.

The alloys frequently used are 1050 and 1070.

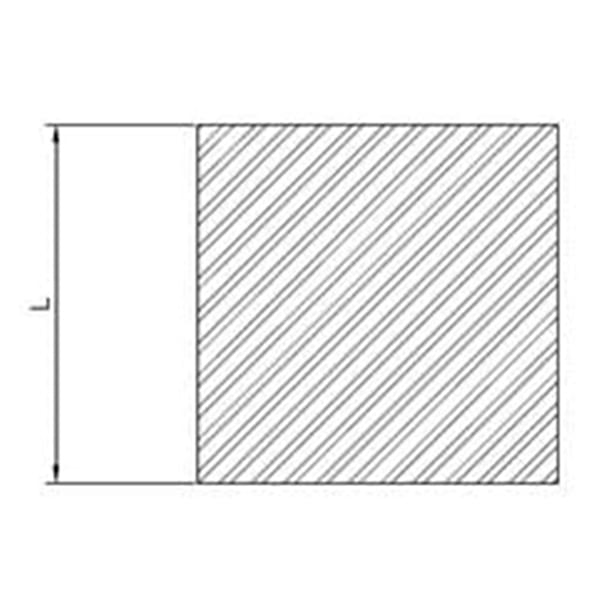

#3 Square bars

Generally made with dimensions that vary from 4 to 50 mm, aluminum square bars can also be customized in small and miniature dimensional tolerances – with dimensions as small as 7 mm for reel format.

Generally made with dimensions that vary from 4 to 50 mm, aluminum square bars can also be customized in small and miniature dimensional tolerances – with dimensions as small as 7 mm for reel format.

These extruded aluminum bars are employed mainly in the mechanical and electromechanical fields, but also in furnishing.

The alloys employed for their production are 1050, 1070, 3103, and 6060.

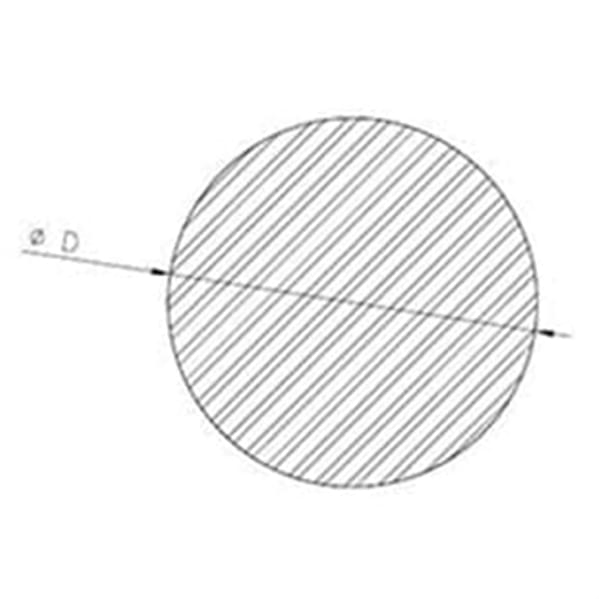

#4 Round bars

Made with 1050, 1070, 3130, and 6060 alloys, aluminum round bars are employed for mechanical, electromechanical, and furnishing applications.

Made with 1050, 1070, 3130, and 6060 alloys, aluminum round bars are employed for mechanical, electromechanical, and furnishing applications.

They are available in two formats: bars – with a minimum order of 200 kg – or reel – with a minimum order of 500 kg.

#5 Fully customized aluminum bars

If you need extruded aluminum bars with particular shapes, uncommon dimensions, or specific surface finishes, with Profall you’re in good hands. In fact, our specialization is to meet our client’s demands thanks to our production of 100% customized extrusions.

Profall produces extruded aluminum bars for each kind of application.

Try the quality of made in Italy aluminum

Why choose Profall’s extruded aluminum bars?

The care we put in the production of our extrusions is the same we give to our customers:

- we listen and understand your needs

- we start producing in about two workweeks since the order date

- we guarantee after-sale support

Also, if you choose our extruded aluminum bars, you will rest assured to:

- obtain the degree of customization you need

- be able to demand bars even in miniature dimensional tolerances

- be able to order even in small batches – starting from 200 kg for bar format, and 500 kg for reel format

- receive your order in a short time wherever you are – we ship worldwide with reasonable shipping costs

Advantages of aluminum

Aluminum has witnessed an incredible widespread use in the last few years thanks to its physical and aesthetic properties, which make it largely appreciated in a huge number of sectors, mostly in the construction and fixtures fields.

But that’s not all. There are many reasons why the extruded aluminum bars demand has grown so rapidly, and that’s because of the qualities of the metal that is used.

In fact, aluminum:

- has great resistance to weather conditions and wear in case of specific finishes

- is easily workable and allows to obtain profiles of all kinds, for every treatment

- doesn’t require maintenance, it only needs a regular surface cleaning

- can be recycled and brought to new life, supporting environmental protection

- in spite of its great resistance, it’s very light

Profall produces extruded aluminum bars for each kind of application.

Try the quality of made in Italy aluminum